نموذج :

DS-20يكتب :

Plunger Pumpسكتة دماغية :

1.5 Inches/38.1mmقطر الاسطوانة :

13-48mmتدفق :

1.5-122.3LPM/0.4-32.3GPMضغط :

7-69MPaميناء الشحن :

Shanghai Port, Chinaضمان :

12 Monthsتحديد:

| معيار التصميم | API-674، الطبعة الثالثة |

| التكوين | مكبس ثلاثي أفقي |

| عدد المكابس | 3 |

| واجب مستمر | 16.6 حصان |

| واجب متقطع | 20.9 حصان |

| طول الضربة | 1.5 بوصة/38.1 ملم |

| تصنيف حمل الإطار | 2700 رطل/1244.7 كجم |

| وزن المضخة (متوسط) | 245 رطلاً/111.13 كجم |

| تصنيف سرعة العمل المتقطع | 600 دورة في الدقيقة |

| تصنيف سرعة العمل المستمر | 475 دورة في الدقيقة |

| الحد الأدنى للسرعة | 100 دورة في الدقيقة |

| الكفاءة الميكانيكية | 90% |

| نظام التزييت | رش، عودة الجاذبية |

| نظام التزييت (اختياري) | مضغوط |

| سعة زيت علبة المرافق | 2 جالون/7.57 لتر |

| نوع زيت التشحيم | SAE 30 |

| نطاق درجة حرارة السائل | من -20 إلى 350 درجة فهرنهايت / من -28 إلى 176 درجة مئوية |

| نوع الصمام | صمام القرص / صمام مقاوم للتآكل |

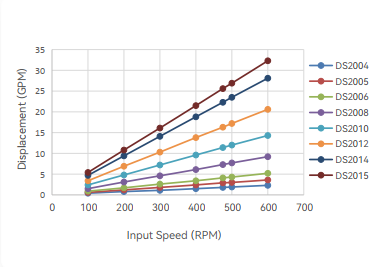

بيانات الأداء (المقياس):

| مضخة نموذج | الغطاس القطر (مم) | النزوح (L/REV) | الحد الأقصى ضغط (ميجا باسكال) | سعة المضخة (لتر/دقيقة) @ سرعة الإدخال (دورة/دقيقة) | ||||||

| 100 | 200 | 300 | 400 | 475 | 500 | 600 | ||||

| دي إس 2004 | 13 | 0.0144 | 69 | 1.5 | 3.0 | 4.2 | 5.7 | 6.8 | 7.2 | 8.7 |

| دي إس 2005 | 16 | 0.0227 | 61 | 2.3 | 4.5 | 6.8 | 9.1 | 11.0 | 11.4 | 13.6 |

| دي إس 2006 | 19 | 0.0326 | 42 | 3.4 | 6.4 | 9.8 | 12.9 | 15.5 | 16.3 | 19.7 |

| دي إس 2008 | 25 | 0.0579 | 23 | 5.7 | 11.7 | 17.4 | 23.1 | 27.6 | 29.1 | 34.8 |

| دي إس 2010 | 32 | 0.0905 | 15 | 9.1 | 18.2 | 27.3 | 36.3 | 43.1 | 45.4 | 54.1 |

| دي إس 2012 | 38 | 0.1302 | 10 | 12.9 | 26.1 | 39.0 | 52.2 | 61.7 | 65.1 | 78.0 |

| دي إس 2014 | 44 | 0.1775 | 8 | 17.8 | 35.6 | 53.4 | 71.2 | 84.4 | 88.9 | 106.4 |

| دي إس 2015 | 48 | 0.2036 | 7 | 20.4 | 40.9 | 60.9 | 81.4 | 96.9 | 101.8 | 122.3 |

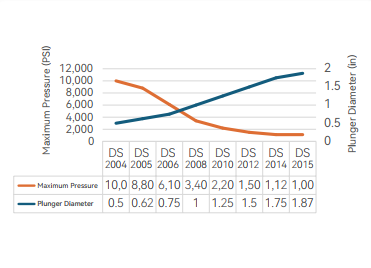

أداء بيانات:

| مضخة نموذج | الغطاس القطر (في) | النزوح (غال/ريف) | الحد الأقصى ضغط (PSI) | سعة المضخة (جالون في الدقيقة) @ سرعة الإدخال (دورة في الدقيقة) | ||||||

| 100 | 200 | 300 | 400 | 475 | 500 | 600 | ||||

| دي إس 2004 | 0.5 | 0.0038 | 10,000 | 0.4 | 0.8 | 1.1 | 1.5 | 1.8 | 1.9 | 2.3 |

| دي إس 2005 | 0.625 | 0.006 | 8,800 | 0.6 | 1.2 | 1.8 | 2.4 | 2.9 | 3 | 3.6 |

| دي إس 2006 | 0.75 | 0.0086 | 6,100 | 0.9 | 1.7 | 2.6 | 3.4 | 4.1 | 4.3 | 5.2 |

| دي إس 2008 | 1 | 0.0153 | 3,400 | 1.5 | 3.1 | 4.6 | 6.1 | 7.3 | 7.7 | 9.2 |

| دي إس 2010 | 1.25 | 0.0239 | 2200 | 2.4 | 4.8 | 7.2 | 9.6 | 11.4 | 12 | 14.3 |

| دي إس 2012 | 1.5 | 0.0344 | 1500 | 3.4 | 6.9 | 10.3 | 13.8 | 16.3 | 17.2 | 20.6 |

| دي إس 2014 | 1.75 | 0.0469 | 1,120 | 4.7 | 9.4 | 14.1 | 18.8 | 22.3 | 23.5 | 28.1 |

| دي إس 2015 | 1.875 | 0.0538 | 1000 | 5.4 | 10.8 | 16.1 | 21.5 | 25.6 | 26.9 | 32.3 |

أحجام الاتصال القياسية:

| نموذج المضخة | الشفط (بالبوصة) | التفريغ (بالبوصة) |

| DS2004-DS2007 | 1.5 | 0.75 |

| DS2008-DS2015 | 1.5 | 1.0 |

| DS2008-DS2015 | 2.0 | 1.5 |

مواد أسطوانة السوائل:

| مواد أسطوانة السوائل | يقذف |

| الفولاذ الكربوني | الحديد المطاوع |

| مواد أسطوانة السوائل | |

| 304 / 316L / 17-4PH / 2205 / 2507 الفولاذ المقاوم للصدأ |

وظيفة

مضخات حقن المواد الكيميائية تلعب هذه المضخات دورًا حيويًا في التطبيقات الصناعية، حيث تضمن استقرار العمليات وكفاءتها من خلال التحكم الدقيق في حجم حقن المواد الكيميائية. تتكيف هذه المضخات مع بيئات تشغيل معقدة ومتنوعة، موفرةً أداءً موثوقًا به في ظروف الضغط العالي أو الوسائط المسببة للتآكل. كما توفر إمكانيات تعديل مرنة، مما يتيح تعديل معدلات التدفق والضغوط بسرعة لتلبية متطلبات التطبيقات المحددة. هذه المرونة لا تعزز الكفاءة التشغيلية فحسب، بل تقلل أيضًا من هدر الموارد بشكل فعال، مما يخفض تكاليف التشغيل للمستخدمين.

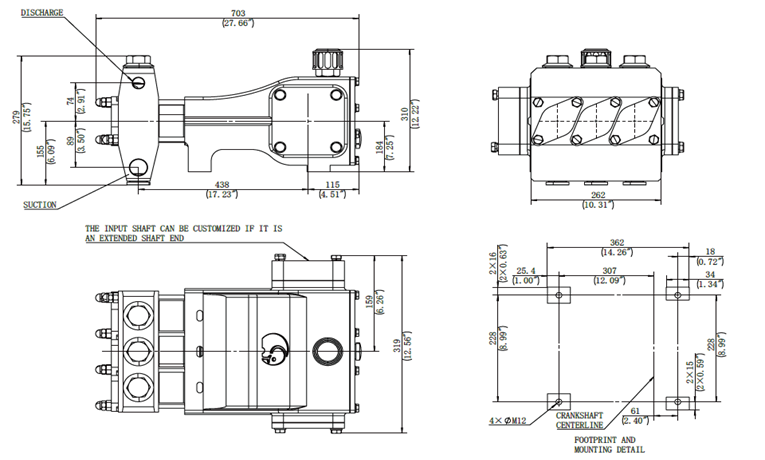

مخطط هندسي الأبعاد

في عمليات استخراج النفط والغاز، وكذلك في عمليات الإنتاج الكيميائي، تلعب مضخات الحقن الكيميائي دورًا بالغ الأهمية. فهي تُدخل مواد كيميائية مُحددة بدقة إلى الوسط المستهدف، وذلك لمنع التآكل، أو تثبيط التكلسات، أو تحسين خصائص السوائل. على سبيل المثال، في حقل النفط والغاز بفضل تطورها، تستطيع هذه المضخات حقن مثبطات التآكل أو المبيدات الحيوية في خطوط الأنابيب، مما يطيل عمر المعدات ويضمن نقلها الآمن. تجعلها مقاومتها القوية للضغط وأدائها التشغيلي المستقر مثالية لظروف التشغيل القاسية. لا تعزز هذه المزايا موثوقية النظام بشكل عام فحسب، بل توفر أيضًا دعمًا قويًا للإنتاج الصناعي المستدام.