نموذج :

CBW-1500يكتب :

Diesel Engine Pumpسكتة دماغية :

150قطر الاسطوانة :

135تدفق :

373-1500 L/minضغط :

5-15 Mpaميناء الشحن :

Shanghai Port, Chinaضمان :

12 MonthsCBW-1500 مضخة معززة لخط الأنابيب هو محرك ثلاثي الأسطوانات ترددي أحادي الفعل مضخة مكبس تعمل بمحرك ديزل، وتتميز بنظام تنظيم تدفق بخمس مراحل.

فريدة من نوعها متردد ثلاثي يقلل التصميم من تذبذب التدفق، مما يضمن تدفقًا أكثر سلاسة للسائل. يتم ضبط التدفق على خمس مراحل عبر علبة تروس دقيقة، مما يوفر سهولة التشغيل وسرعة التكيف مع متطلبات التدفق المتغيرة في مختلف ظروف التشغيل. الانتقالات بين الإعدادات سلسة وخالية من الصدمات. بالإضافة إلى ذلك، يشتمل نظام المضخة على نظام تبريد وتزييت متكامل. تعمل مروحة التبريد بالتزامن مع المحرك، بينما يقوم نظام التزييت القسري بتزييت الأجزاء المتحركة بدقة، مما يقلل من التآكل ويطيل عمر المعدات.

تتميز هذه المعدات بكفاءة تشغيلية فائقة، إذ تحافظ على أداء ثابت في مختلف ظروف التشغيل. سواءً في أنظمة خطوط الأنابيب الصناعية واسعة النطاق التي تتطلب تشغيلاً مستمراً لفترات طويلة، أو في تطبيقات تعزيز الضغط الصغيرة والمتوسطة الحجم ذات دورات التشغيل والإيقاف المتقطعة، فإن هذه الوحدة توفر باستمرار أداءً موثوقاً بفضل تصميمها الهيكلي وتوافقها الأمثل مع الطاقة. كما تضمن تدفقاً مستقراً للسوائل داخل خطوط الأنابيب ضمن نطاقات ضغط محددة، ما يلبي المتطلبات الصارمة لتعزيز الضغط بكفاءة وثبات في بيئات التشغيل المعقدة.

المعايير والمواصفات الفنية

| يكتب | مضخة مكبسية أفقية ثلاثية الأسطوانات ترددية أحادية الفعل |

| شوط (مم) | 150 |

| قطر الأسطوانة (مم) | 135 |

| معدل التدفق (لتر/دقيقة) | 1500 979 728 557 373 |

| الضغط (ميجا باسكال) | 5 7.5 10 13 15 |

| سرعة الإدخال (دورة/دقيقة) | 160 |

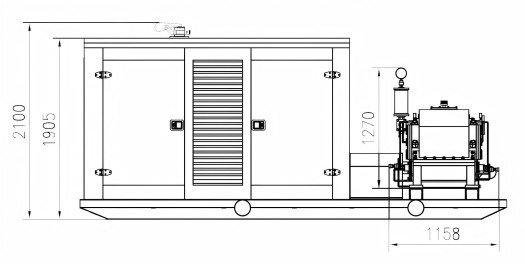

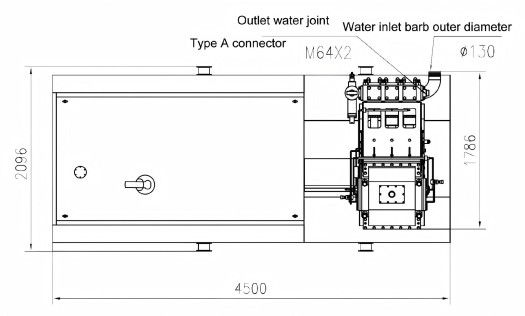

| الأبعاد (مم) | 4500*2096*2100 |

| الوزن (كجم) | 5980 |

| طراز يعمل بالديزل | QSC8.3-C260 |

| قوة محرك الديزل (كيلوواط) | 194 |

| السرعة المقدرة (دورة/دقيقة) | 1700 |

الوظائف

ال مضخة معززة لخط الأنابيب يلعب دورًا محوريًا في أنظمة نقل السوائل المختلفة. فهو يعالج مشكلات انخفاض الضغط داخل خطوط الأنابيب الناتجة عن فقدان الضغط بسبب الاحتكاك، أو اختلاف الارتفاع، أو عدم كفاية الضغط الأولي. ومن خلال الحركة الترددية الدورية للمكابس داخل الأسطوانة، يحول الطاقة الميكانيكية من المحرك الرئيسي إلى طاقة ضغط السائل، مما يرفع ضغط السائل داخل خط الأنابيب. وهذا يضمن توصيل السائل بثبات إلى الموقع المستهدف بالضغط ومعدل التدفق المحددين. في الإنتاج الصناعي، يوفر القوة الدافعة لنقل السوائل عبر خطوط الأنابيب لمسافات طويلة ويحافظ على ضغط العمليات. في تطوير حقول النفط، وهندسة التعدين، وغيرها من المجالات، يُستخدم لتعزيز ضغط إمدادات المياه، وضخ الآبار العميقة، والتنظيف عالي الضغط، أو حقن التكوينات. بفضل قدرته الفائقة على تعزيز الضغط، وتدفقه المستقر، وقابليته للتكيف مع ظروف التشغيل المعقدة، أصبح من المعدات الأساسية لضمان التشغيل الفعال والآمن والموثوق لأنظمة نقل السوائل.

طلب

تُعدّ مضخات تعزيز الضغط في خطوط الأنابيب، بفضل قدراتها الفريدة على رفع الضغط وخصائصها التشغيلية المتميزة، من المعدات الأساسية في العديد من الصناعات. ففي قطاع النفط والكيماويات، تُستخدم هذه المضخات على نطاق واسع لنقل النفط الخام، والمنتجات البترولية المكررة، ومختلف المواد الكيميائية عبر خطوط الأنابيب. وتتغلب هذه المضخات بفعالية على فقدان الضغط أثناء النقل لمسافات طويلة عبر خطوط الأنابيب، مما يضمن تدفقًا مستقرًا للمواد بين مراحل المعالجة، مثل التفاعل والفصل والتخزين. أما في قطاع الطاقة، فتؤدي مضخات تعزيز الضغط دورًا حيويًا في كلٍ من ضغط مياه تغذية غلايات محطات توليد الطاقة ونقل السوائل ذات درجات الحرارة العالية لتطوير الطاقة الحرارية الأرضية، وذلك بفضل مقاومتها لدرجات الحرارة والضغوط القصوى. وفي صناعات التعدين والمعادن، تُسهّل هذه المضخات نقل المواد اللزجة، وأنظمة النقل الهيدروليكية، وضغط الدوران لأنظمة التبريد المختلفة، مما يضمن استمرارية واستقرار عمليات الإنتاج.